Products & Services

” NIS, has the experience and training to get the job done right the first time. “

Featured Video

SPECIALTY OVERHEAD LIFTERS

(Click the icon above to go to overhead lifters)

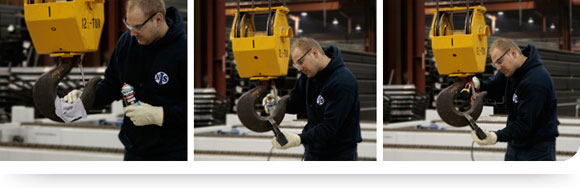

Magnetic Particle Inspection

Magnetic Particle Inspection: Magnetic Particle Testing (also called magna-flux testing) is a nondestructive test method used to detect problems at or near the surface in ferromagnetic materials. NIS conducts magnetic particle testing for items such as:

- Eyebolts

- Crane hooks

- Welds on specialty lifters

- Swivel hoist rings

- End Effectors

- Hi-Lo Forks

The process for magnetic particle testing at NIS is outlined below:

- Physical characteristics of the test item (size, type, serial number, etc.) are recorded on an inspection report.

- Test item is inspected visually for elongation, wear, deformation, and missing capacity markings.

- The part is cleaned with a special cleaner to prepare it for magnetic particle testing.

- The part is magnetized.

- The part is sprayed with a magnetic particle spray.

- After the part has been prepared with the particle spray, it is inspected for cracks by a certified technician using a black light and magnetic yoke.

- The technician having made the necessary observations, the part is demagnetized and cleaned.

- Each passing test item is tagged with a color coded inspection tag, demonstrating that it has been checked.

- Test items which do not pass inspection will be tagged with a caution tag as well as a red paint mark.

- Lastly, NIS provides a computer generated report on a spreadsheet with a certificate governing regulatory standards for all passing test items.

Other services we provide include: